Want to find out how KUNBA packaging machines can benefit you? Contact and consult our team of experts to find out about packaging solutions tailored to your needs!

Introduction

In the fast-paced world of manufacturing and logistics, efficient packaging is essential to ensure product quality and streamline operations. Pallet wrappers have become a must-have for a variety of industries, including food packaging, pharmaceutical packaging, and more. These machines securely wrap products on pallets, ensuring they are protected during storage and transportation.

This article explores what a pallet wrapper is, its benefits, applications, and how to choose the right one for your business.

I.What is a pallet wrapper?

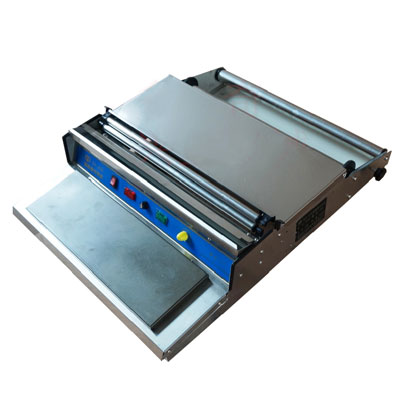

A pallet wrapper (or pallet wrapper) is an automatic or semi-automatic packaging machine used to wrap products placed on a pallet with stretch film, shrink film, or other protective materials. The machine ensures that the goods remain stable, secure, and protected from dust, moisture, and damage during transportation.

Key Components of a Pallet Wrapper:

Film Roll Holder – used to hold the stretch film or shrink film.

Wrapping Mechanism – used to rotate the pallet or wrap the film around the product.

Cutting and Sealing System – used to cut and seal the film to make the package tight.

Conveyor system – used to move pallets in and out of the machine (automated models).

Control panel – for the operator to adjust settings such as film tension and speed.

II.Benefits of using a pallet wrapper

1. Enhanced product protection – prevents shifting, dust contamination and moisture.

2. Improved efficiency – automates packaging, reduces labor costs and speeds up packaging lines.

3. Cost savings – optimizes film utilization and minimizes waste compared to manual wrapping.

4. Improved stability – keeps products secure on the pallet or during transport, reducing the risk of damage.

5. Versatility – suitable for a wide range of pallet sizes and products (food, electronics, pharmaceuticals).

III.Applications of pallet wrappers

Pallet wrappers are used in a wide range of industries, including:

1. Food and Beverage Industry

Packaging meat, poultry, dairy and ready-to-eat foods on pallets.

Ensures hygiene and extends shelf life through sealing.

2. Pharmaceuticals and Medical Supplies

Protects sterile medical devices and pharmaceutical pallets.

Meets safety and contamination prevention standards.

3. Electronics and Retail

Secure fragile electronics, appliances, and retail products on display pallets.

4. Logistics and Warehousing

Stabilize goods on pallets to ensure safe transportation and storage.

IV.How to Choose the Right Pallet Wrapping Machine

When choosing a Pallet Wrapping Machine, consider the following factors:

1. Level of Automation

Manual/Semi-automatic – Best for small batch production.

Fully Automatic – Best for high-speed production lines.

2. Film Type

Stretch Film – Often used for pallet stability.

Shrink Film – Provides a tighter seal for retail packaging.

3. Pallet Size and Compatibility: Make sure the machine fits your pallet size.

4. Production Speed: High-speed machines are suitable for large-scale production.

5. Durability and Maintenance: Choose a machine with a solid structure and easy to clean.

Conclusion

Traypackers are a game-changer for companies looking to improve packaging efficiency, reduce costs, and enhance product safety. Whether in food processing, pharmaceuticals, or logistics, investing in the right traypacker can significantly optimize your operations.

By understanding your production needs and choosing a machine with the right features, you can get a faster, more reliable, and more cost-effective packaging solution.