Key Features

Various content

Can print graphics, various barcodes, QR codes, dates, and more

Real-time status

Real-time status monitoring of machine status and ink level for easy maintenance

Multi-language support

Can be expanded to the languages of the exporting countries, facilitating product proofing

Remote communication

Can remotely transmit coding content for ease of use

|

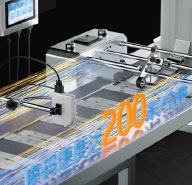

Dual-core architecture Clear inkjet printing at 200 m/min production line speeds |

|

Specially developed account management system Multiple products per shift, multiple products per shift, |

|

New, self-developed system for easy operation. Equipped with a 7-inch capacitive touchscreen for |

|

Automatically generate live barcodes/traceability codes. Quickly generate massive barcodes. |

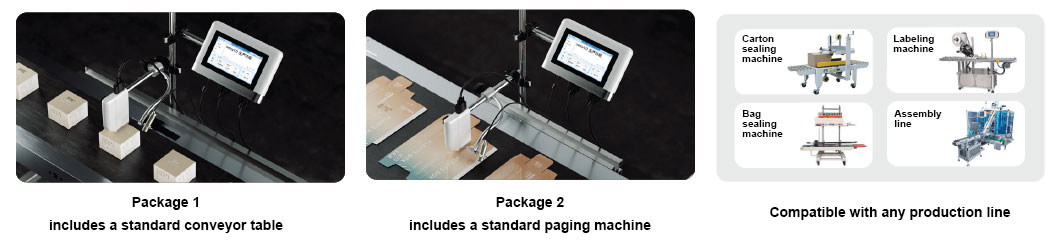

Matching Equipment

Product Parameters

| Product Name | KUNBA U7 Inkjet Printer |

| Material | PC Material |

| Screen Size | 7-inch Touchscreen |

| Environmental Requirements | Temperature 0-40°C, Humidity 10-80% |

| Interfaces | Ethernet, USB, DB9 Data, DC Power Supply, DB15 Printhead |

| Operation Language | Chinese, English, and other languages (French, German, Spanish, Portuguese, Russian, Korean, Japanese, and custom languages available upon request) |

| Dimensions | 152*223*32mm |

| Gross Weight (Standard Photoelectric Sensor) | 3.48kg |

| Print Head | TIJ Thermal Inkjet Printhead |

| Printing Height | 1-25.4mm |

| Printing Accuracy | Standard 600 DPI |

| Printable Materials | 99% of products on the market, including boards, cartons, pipes, cables, metals, plastics, etc. |

| Operating system | Linux |

| Information storage | 256MB |

| Counting sequence | 20-digit characters |

| Print font library | Default Hongmeng font; customers can install their own fonts |

| Packaging dimensions | 440*240*135mm |

| Printing speed | 200m/min |

| Printing distance | 3-5mm |

| Printing content | Barcodes, letters, numbers, Chinese characters, images, dates, work groups, counters, graphics, dynamic text, device names, scanners, databases |

| Applicable ink cartridge types | Dry, water-based, and oil-based ink cartridges |

| Applicable ink cartridge colors | Black, white, red, yellow, blue, green, invisible |

Strictly implement 23 major tests

| U7 Test Items | U7 Test Conditions | U7 test results |

| Power On/Off Stability Test | Tested with PLC-controlled power on/off for 120 hours | 0K |

| Constant Humidity Test | Temperature: +45°C, Humidity: 93% RH, Duration: 48 hours | 0K |

| Temperature Shock Test | Temperature: -20°C to +70°C, Cycles: 4, Duration: 24 hours | 0K |

| Low-Temperature Storage Test | Temperature: -20°C, Duration: 24 hours | 0K |

| High-Temperature Storage Test | Temperature: +70°C, Duration: 24 hours | 0K |

| Low-Temperature Operation Test | Temperature: -10°C, Status: Powered on, Duration: 24 hours | 0K |

| High-Temperature Operation Test | Temperature: +55°C, Status: Powered on, Duration: 24 hours | 0K |

| Voltage and Current Test | Voltage: 90V, 269V | At 90V input voltage, the maximum current is 0.206A and the minimum current is 0.008A. At 269V input voltage, the maximum current is 0.105A and the minimum current is 0.019A. |

| Disassembly and Assembly Test | Disassembly and installation 10 times | 0K |

| Package Drop Test | Drop height: 1m Drop location: one edge, six sides of a triangle | |

| Insulation Withstand Voltage Test | M mode: Applied voltage 1.5kV, 50Hz, 5mA, 1 minute DC mode: Applied voltage 1kV, 1 minute |

0K |

| ESD Test | Air discharge: ±6kV, ±8kV Contact discharge: ±6kV, ±8kV |

0K |

| Electrical Rapid Burst Test | L1 channel: ±3kV (pulse frequency: 5kHz, 100kHz) N1 channel: ±3kV (pulse frequency: 5kHz, 100kHz) PE channel: ±1.5kV (pulse frequency: 5kHz, 100kHz) |

0K |

| Printhead Vibration Test | Intensity: 20 High Frequency: 50Hz Amplitude: 1:66 Low Frequency: 20Hz Amplitude: 2.67 Duration: 48 hours |

0K |

| Printhead Low-Temperature Storage Test | Temperature: -20°C Time: 24 hours | 0K |

| Printhead High-Temperature Storage Test | Temperature: +70°C Time: 24 hours | 0K |

| Printhead Impact Test | A 12kg object was used to impact the nozzle at speeds of 20, 40, 60, 80, and 100 m/min. The impact distance was 1.8 cm. The impact object was held 10 cm from the edge of the production line. | 0K |

| Printhead ESD Test | Air discharge: ±6kV, ±8kV Contact discharge: ±6kV, ±8kV |

0K |

| Printhead Low-Temperature Operation Test | Temperature: -10℃ Status: Power on Time: 24h | 0K |

| Printhead Electrical Rapid Burst Test | L1 channel: ±3kV (pulse frequency: 5kHz, 100kHz) N1 channel: ±3kV (pulse frequency: 5kHz, 100kHz) PE channel: ±1.5kV (pulse frequency: 5kHz, 100kHz) |

0K |

| Printhead Vibration Test | Frequency 35Hz, start vibration test 48H | 0K |

| Printhead High-Temperature Operation Test | Temperature: ±55℃ Status: Power on Time: 24h | 0K |

| Printhead Temperature Shock Test | Temperature: -20~+70℃ Cycle times: 4 times Time: 24h | 0K |